Tektronix oscilloscope plays a role in taking the mystery out of record home runs

This year, American baseball batters have hit 2,875 homers in the first 1,122 games this season, an average of 2.56 per game, up 12% from the same period in 1999. In April, for example, record 931 home runs were hit, including 57 in one day and 262 in one week. And for those players fantasizing about becoming the next Hank Aaron, 22 players are on pace to hit at least 48 homers. The record is only five players in a single season hitting that many.

Explanations abound: ballparks are smaller, players are bigger, and pitchers are lousier. Number one among the conspiracy theories is that the baseballs are livelier, probably made by golf ball manufacturers to satisfy fans who love the long ball.

To quiet complaints, baseball commissioner Bud Selig called for a scientific study to determine if the baseball bats manufactured for the game conform to size, weight, and impact standards. Selig hired Professor James Sherwood of the mechanical engineering department at the University of Massachusetts at Lowell to evaluate today's baseball bats. Sherwood heads the University's Baseball Research Center, which houses one of only two baseball testing devices in existence that swings a bat into a moving ball Figure 1.

Baseball research facility covers all levels of play

The UMass-Lowell Baseball Research Center was started with a grant of $400K from Major League Baseball and Rawlings Sporting Goods. The scope of research for the UMass-Lowell Baseball Research Center includes studying the performance of baseballs and bats at all levels of play. To date, the center has concentrated on the collegiate, major league, and high school levels. The lab is the official certification center for all bats used in NCAA baseball and all nonwood bats (nonwood meaning anything other than solid wood, e.g. composite and laminated wood) used in at the professional baseball minor levels.

The lab has a Baum Hitting Machine (BHM) (cost $350K), which is capable of swinging a bat at speeds up to 100 mph and pitching a baseball at speeds up to 100 mph. The setup can hit the target position on the bat with pinpoint accuracy (in the cage). The operator prescribes the desired bat swing speed, pitch speed, and impact location. The instrumentation on the machine allows for the measurement of the bat swing speed, pitch speed, and batted ball speed 9-in, 13-in, and 72-in (Figure 2) down line from the bat/ball collision.

The machine is a state-of-the-art device for measuring bat performance as a function of axial location along the bat and ball performance. As a complement to the BHM, is a Tektronix TDS 220 oscilloscope, a power supply, a pivoting bat fixture that holds a bat, a steel scale (Figure 3).

and an optical sensor. (Figure 4).

Critical to understanding bat performance is knowing the bat's MOI (mass moment of inertia). The higher the MOI, the more difficult it is for a player to swing the bat through the ball. The BHM swings the bat at the prescribed speed regardless of the bat's MOI. The machine's servomotor simply delivers whatever power is required to meet the prescribed swing speed. In order to understand the complete picture of bat and/or ball performance, the batted ball speeds measured using the BHM must account for the bat's MOI. Thus, the MOI is a critical ingredient to the complete understanding of batted-ball speed using the BHM.

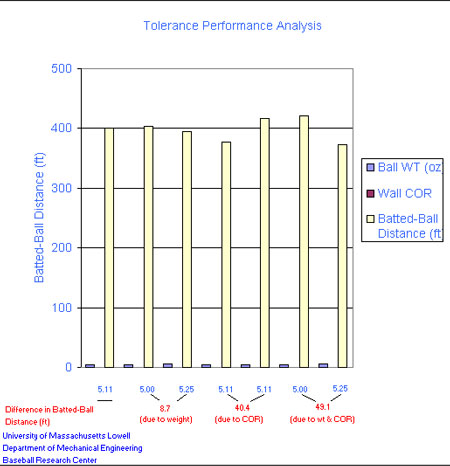

The use of the TDS 220 oscilloscope to measure the MOI assists in developing this complete and credible understanding of bats in relation to how fast a player can swing them. According to standards, a ball traveling at 100 miles per hour hitting a wall of two-inch thick white ash should bounce back at 54.6 ± 3.2 miles per hour.

"Previous to using the TDS 220 to measure the period, the testing was done by a person counting the number of swings for the "bat pendulum" and measuring the time to complete 30 swings using a stopwatch," says Sherwood. "Simple errors in counting the number of periods (due to distractions in the workspace) and the reaction time for the person to start and stop the watch introduce errors into the MOI calculation. The TDS 220 gives a visual record of the count and accurate timing when it is used in conjunction with the optical sensor."

Testing fixture designed for repeated tests

The bat fixture (With Larry) was designed using solid modeling techniques and steriolithography. It is designed for ease of use and fixture repeatability (so that other labs can have the exact test hardware). The fixtures are calibrated using a slender rod and the theoretical relationship between the inertial and geometric properties of the rod. A bat can be placed easily and accurately into the fixture in seconds. The fixture pivots on low friction bearings and the degradation of free bat pendulum pivot is negligible.

A pin on the top of the pivoting fixture is used to count the periods of the pendulum as the pin passes through an optical sensor. The pin passes through the 5-mm optical sensor and the change in voltage is read on the oscilloscope. Typically, the time is recorded for four periods. The distance between the knob and the pivot point is also recorded. The inertia is calculated from the free pendulum period, pivot distance and previously recorded bat length, cg, and weight (compensating for the fixture calibration).

By knowing the inertia of the bat, the bat's "swingability" can be estimated. A study was performed to relate bat inertia to swing speed. A relationship was derived using weighted bats and collegiate ball players. A typical aluminum bat can be swung 4 mph faster than the average wood bat, increasing the batted-ball velocity.

Lab results yield comparable simulations

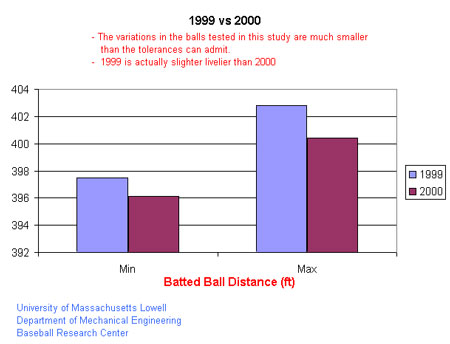

Sherwood's research showed that this year's ball actually traveled 1.4 ft less in simulations than last year's ball (Figures 5 A and B).

"The bottom line is that the 2000 baseballs and the 1999 baseballs are essentially the same," said Sherwood. But homerun theories die hard. The latest is that this year's Major League Baseball's silhouette logo may make it easier for batters to read the rotation of the pitch. It could be another job for the TDS 220.